close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2024-11-19 Origin: Site

In modern metal manufacturing, the cold drawing process stands as one of the most precise and efficient methods for producing high-quality metal products. Whether you're working with steel, copper, or aluminum, understanding cold drawing can help you achieve superior dimensional accuracy and enhanced mechanical properties. This comprehensive guide explores everything from basic principles to advanced applications, empowering manufacturers and engineers to make informed decisions about their metalworking processes.

Cold drawing is a metalworking process performed at room temperature that improves material strength by 20-50% while achieving tolerances as tight as ±0.05mm

The process involves pulling metal through a die to reduce cross-sectional area, enhancing surface finish to Ra 0.4-1.6 micrometers

Common applications include cold drawn seamless tube production, wire manufacturing, and precision bar stock for automotive and aerospace industries

Proper lubrication and die selection are critical factors that determine final product quality and production efficiency

Cold drawing offers significant advantages over hot working processes including better dimensional control, superior surface quality, and reduced material waste

Cold drawing is a metalworking technique where metal is pulled through a specially designed die at room temperature to reduce its cross-sectional area and achieve specific dimensional requirements. Unlike hot forming processes that require heating the material above its recrystallization temperature, the cold drawing process works the metal in its solid state, typically below 30% of its melting point.

The fundamental principle involves applying tensile force to pull the workpiece through a converging die opening. As the metal passes through, it undergoes plastic deformation, resulting in a reduction of diameter or thickness while simultaneously increasing length. This controlled deformation not only shapes the material but also fundamentally alters its internal structure through a phenomenon called work hardening or strain hardening.

According to materials engineering research from the National Institute of Standards and Technology, the cold drawing process can be applied to various metal forms including wire, rod, bar, tube, and specialized profiles. The versatility of this technique makes it indispensable in industries ranging from construction to electronics manufacturing.

The cold drawing process follows a carefully orchestrated sequence to ensure optimal results:

1. Material Preparation: The process begins with cleaning the metal surface to remove scale, rust, or contaminants. Surface preparation typically involves chemical pickling or mechanical descaling, followed by a phosphate coating that serves as a base for lubrication. This preparatory stage is crucial because any surface imperfections will be magnified during the drawing operation.

2. Lubrication Application: A specialized lubricant is applied to reduce friction between the metal and die surfaces. Common lubricants include soap solutions for wire drawing, oil-based compounds for bar drawing, and dry lubricants like molybdenum disulfide for extreme pressure applications. Proper lubrication can reduce drawing force by 30-40% and significantly extend die life.

3. Pointing: The leading end of the workpiece is reduced in diameter to fit through the die opening. This pointed section provides the grip needed to start the drawing process and is typically achieved through swaging, rolling, or machining.

4. Drawing Through the Die: The pointed end is gripped by a drawing mechanism (such as a bull block, chain drive, or capstan), and the material is pulled through the die at controlled speeds ranging from 10 to 100 meters per minute depending on material type and reduction ratio. The die geometry features a bell-shaped entry zone, a working zone where reduction occurs, and a bearing surface that sizes the final product.

5. Multiple Passes: For significant size reductions, the material typically undergoes multiple drawing passes with intermediate annealing when necessary. Each pass typically reduces the cross-sectional area by 15-30%, with total reductions potentially reaching 90% or more across multiple operations.

6. Final Processing: After drawing, the material may undergo stress relieving, straightening, or cutting to final lengths. Quality inspection verifies dimensional accuracy, surface finish, and mechanical properties meet specifications.

During the cold drawing process, metal grains become elongated in the direction of drawing, creating a fibrous structure that enhances strength. The dislocation density within the crystal structure increases dramatically, impeding further plastic deformation and resulting in work hardening. This phenomenon can increase yield strength by 20-50% while simultaneously reducing ductility by 10-30%.

The degree of work hardening depends on the reduction ratio, material composition, and initial microstructure. Research published in metallurgical engineering journals demonstrates that properly controlled cold drawing can produce predictable and desirable mechanical property changes tailored to specific applications.

Bar drawing processes produce solid cross-sections ranging from small diameter wire to large bars several inches thick. This method commonly uses draw benches for longer products or bull blocks for coil-to-coil operations. Bar drawing achieves exceptional straightness tolerances of 0.5mm per meter and concentricity within 0.05mm, making it ideal for precision shafts, fastener stock, and machining bar applications.

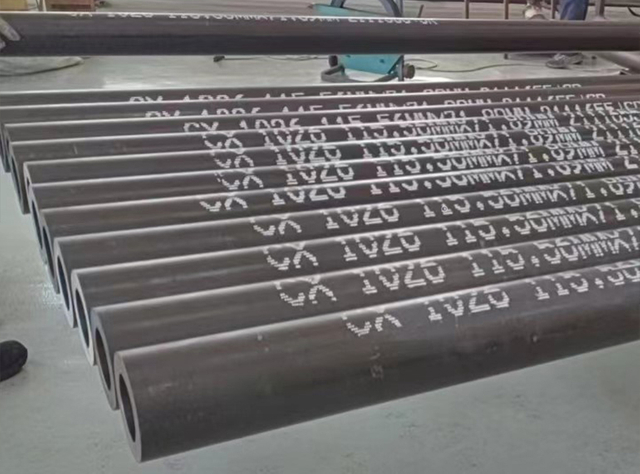

Tube drawing encompasses several specialized techniques depending on whether internal dimensions, external dimensions, or both require control. The process for creating cold drawn seamless tube typically employs either a fixed plug, floating plug, or mandrel to support the internal diameter while the die controls the outer diameter. This dual control enables precise wall thickness tolerances of ±5-10% while achieving excellent surface finishes both inside and out.

Tube sinking, a variation without internal support, reduces only the outer diameter while wall thickness increases proportionally. This simpler process suits applications where internal dimensional precision is less critical.

Wire drawing reduces materials to fine diameters, sometimes as small as 0.025mm for specialty applications like electronics and medical devices. The process typically involves multiple sequential dies arranged in a drawing machine, with each die producing an incremental reduction. Modern wire drawing machines can operate continuously at speeds exceeding 30 meters per second for fine wire production.

Shape drawing produces non-circular cross-sections including squares, hexagons, ovals, and custom profiles. Dies for shape drawing require precise design to ensure uniform metal flow and prevent defects. This technique finds applications in automotive trim, architectural elements, and specialized mechanical components.

The cold drawing process works effectively with numerous metals and alloys, though success depends on material characteristics including ductility, work hardening rate, and surface condition. Here's a comprehensive overview:

| Material Type | Typical Applications | Maximum Reduction Per Pass | Special Considerations |

|---|---|---|---|

| Low Carbon Steel | Wire, fasteners, automotive parts | 20-30% | Excellent drawability, may require annealing after 60-70% total reduction |

| Stainless Steel (304/316) | Tubing, medical instruments, food equipment | 15-25% | High work hardening rate, requires annealing after 30-40% total reduction |

| Copper & Copper Alloys | Electrical wire, plumbing, heat exchangers | 25-35% | Soft and ductile, excellent for fine wire down to 0.025mm |

| Aluminum Alloys (6061/7075) | Aerospace components, electrical conductors | 20-30% | Prone to galling, requires effective lubrication and die material selection |

| Brass (C26000/C36000) | Decorative trim, musical instruments, plumbing fittings | 30-40% | Good formability, monitor for dezincification in certain environments |

| Nickel Alloys (Inconel) | Chemical processing, aerospace, marine applications | 12-20% | Very high strength, challenging to draw, requires carbide dies |

Material selection significantly impacts process parameters and equipment requirements. Understanding material behavior under cold working conditions, as documented in NIST metallurgy standards, is essential for achieving optimal results and preventing defects.

Cold drawing offers numerous benefits that make it preferable to alternative manufacturing methods in many applications:

Superior Dimensional Accuracy: The process consistently achieves tolerances ranging from ±0.05mm for small precision components to ±0.13mm for larger products, depending on size and specification requirements. This precision eliminates or reduces secondary machining operations, lowering overall manufacturing costs by 15-30%.

Enhanced Surface Finish: Cold drawn products typically exhibit surface roughness values between Ra 0.4-1.6 micrometers, significantly smoother than hot-rolled equivalents which range from Ra 6-25 micrometers. This superior finish improves appearance, reduces friction coefficients by 20-40% in moving parts, and enhances corrosion resistance.

Improved Mechanical Properties: Work hardening during the cold drawing process increases tensile strength by 20-50% and yield strength by 30-60% compared to annealed material. For example, low carbon steel can increase from 300 MPa yield strength to 450-500 MPa after cold drawing. This strength enhancement allows designers to use smaller cross-sections, reducing material costs by 10-25% and product weight.

Better Straightness and Concentricity: Cold drawn bars achieve straightness tolerances of 0.5mm per meter or better, with concentricity deviations as low as 0.05mm. These characteristics are critical for precision shafts, hydraulic cylinders, and rotating components operating at speeds above 1000 RPM.

Material Efficiency: Unlike machining operations that remove material as chips (wasting 20-50% of raw material), cold drawing simply reshapes metal with less than 2% material loss. Combined with the elimination of secondary operations, this efficiency translates to cost savings of 15-35% and significant environmental benefits.

Consistent Quality: The controlled nature of the cold drawing process produces uniform mechanical properties and dimensions throughout production runs, with typical variation coefficients below 3%. This consistency is particularly valuable for high-volume manufacturing where part interchangeability is essential.

Versatility: From wire thinner than 0.025mm to bars 150mm in diameter, cold drawing accommodates an enormous range of sizes and shapes. Custom profiles can be produced economically for specialized applications with production runs as low as 500kg for some geometries.

Despite its advantages, the cold drawing process presents certain limitations that manufacturers must consider:

Work Hardening Limits: As material is drawn, work hardening eventually makes further reduction difficult or impossible without intermediate annealing. Annealing cycles add 4-8 hours processing time and 5-15% to production costs, particularly for high-reduction applications requiring multiple annealing steps.

Size Limitations: While excellent for products up to 150mm diameter, cold drawing becomes economically impractical for very large cross-sections due to equipment force requirements exceeding 500 tons. Hot forming methods typically prove more suitable for sections above 200mm diameter.

Initial Material Requirements: The process requires starting material with good surface quality (Ra < 6 micrometers) and relatively uniform dimensions (±0.5mm tolerance). Poor quality feedstock leads to defects, accelerated die wear reducing tool life by 40-60%, and production interruptions.

Die Costs and Maintenance: Precision dies represent significant capital investment ranging from $500 for simple wire dies to $15,000+ for complex tube drawing mandrels. Dies require regular maintenance or replacement after processing 50-500 tons of material depending on hardness. Custom shapes necessitate specialized tooling that may not be cost-effective for production runs below 1000kg.

Material Restrictions: Very brittle materials (elongation < 5%) or those with extremely high work hardening rates prove difficult or impossible to cold draw. Each material requires specific process parameters and tooling designs developed through experience and testing.

Die design profoundly influences product quality, production efficiency, and tool life. Key geometric parameters include:

Reduction Angle (Die Semi-Angle): The angle of the die's working zone typically ranges from 6° to 24° total included angle (3° to 12° semi-angle). Smaller angles of 6-8° reduce drawing force by 15-25% and improve surface finish but require longer dies and slower speeds. Larger angles of 16-24° increase productivity by 20-30% but may cause surface defects or internal cracking. Industry standards recommend optimal angles between 12-16° total (6-8° semi-angle) for most steel drawing applications, balancing force reduction with production efficiency.

Bearing Length: The cylindrical bearing section following the reduction zone determines final product diameter and surface finish. Bearing lengths typically equal 0.3-0.5 times the final diameter (e.g., 3-5mm bearing for 10mm diameter product), with longer bearings improving dimensional control to ±0.025mm but increasing friction force by 10-20%.

Entry Zone Radius: A bell-shaped or radiused entry with radius 3-6 times the wire/bar diameter helps guide material into the die and facilitates lubricant retention. Proper entry geometry prevents scratching and assists in establishing smooth material flow, reducing defect rates by 30-50%.

Reduction ratio, defined as the percentage decrease in cross-sectional area per pass, directly affects work hardening, surface quality, and process efficiency. Most operations use reductions between 15-30% per pass, balancing productivity with material formability. Excessive reduction above 35% causes excessive work hardening (hardness increases > 15 HRC per pass), increased drawing force beyond equipment capacity, and potential defects including center bursting or surface tearing.

For multi-pass operations, the total reduction formula is: Total % = [1 - (Afinal/Ainitial)] × 100, where A represents cross-sectional area. Achieving 90% total reduction typically requires 6-10 passes with intermediate annealing.

Drawing speed influences production rate, temperature rise, and surface finish. Higher speeds increase productivity but generate more frictional heat (temperature rises of 50-150°C possible at speeds above 50 m/min) that can degrade lubricant effectiveness and affect mechanical properties through localized annealing effects. Typical speeds range from:

• Heavy bar drawing: 10-30 m/min

• Medium wire/rod: 30-100 m/min

• Fine wire drawing: 100-2000 m/min (up to 30 m/sec for specialty applications)

Speed optimization depends on material thermal conductivity, reduction ratio, and cooling capacity, with optimal speeds determined through trial runs measuring temperature and surface quality.

Effective lubrication is absolutely critical for successful cold drawing. Lubricants serve multiple functions: reducing friction coefficients from 0.3-0.5 (dry) to 0.05-0.15 (lubricated), cooling the die and workpiece, protecting surfaces from wear, and facilitating metal flow. Selection depends on material type, reduction severity, and drawing speed. Proper lubrication can reduce drawing force by 30-40% while extending die life by 3-5 times compared to inadequate lubrication.

Common lubricant systems include:

• Soap-based (sodium/calcium stearate) for wire drawing - friction coefficient 0.08-0.12

• Oil-based emulsions for bar/tube drawing - friction coefficient 0.05-0.10

• Polymer coatings for extreme reductions - friction coefficient 0.04-0.08

• Dry film lubricants (MoS₂) for stainless steel - friction coefficient 0.05-0.09

The versatility of the cold drawing process has made it indispensable across numerous industries:

Automotive Industry: Cold drawn steel bars provide precision raw material for engine components (camshafts, crankshafts with tolerances ±0.05mm), transmission shafts, steering components, and suspension parts. The process delivers the tight tolerances and excellent surface finishes (Ra 0.8-1.6 μm) required for high-performance automotive applications operating at speeds up to 6000 RPM. Cold drawn seamless tube finds use in hydraulic systems (operating pressures 200-350 bar), fuel lines, and structural applications, with annual global automotive consumption exceeding 15 million tons.

Aerospace: Aircraft manufacturers rely on cold drawn aluminum alloys (7075-T6, 2024-T3), titanium (Ti-6Al-4V), and nickel alloys (Inconel 718) for structural components, hydraulic tubing (operating pressures up to 5000 psi), and control cables. The process meets stringent dimensional tolerances (±0.025mm typical) and mechanical property requirements while providing full material traceability and certification documentation per AS9100 standards.

Construction: Reinforcing bar, prestressing wire (tensile strength 1570-1860 MPa), and structural shapes utilize cold drawing to achieve specified strength grades. The process enhances structural performance by 25-40% while enabling lighter, more economical designs that reduce building weight by 10-20% in some applications.

Medical Devices: Surgical instruments, catheter tubing (wall thickness 0.05-0.5mm), guidewires (diameters 0.25-3mm), and implantable components often employ cold drawn stainless steel (316L) or specialty alloys (Nitinol, MP35N). The biocompatibility, corrosion resistance (pitting resistance > 900 mV), and precision achievable through cold drawing (tolerances ±0.013mm) make it ideal for medical applications requiring FDA/ISO 13485 compliance.

Electronics: Copper wire for electrical conductors (conductivity > 100% IACS), connector pins (tolerances ±0.01mm), and specialty alloy wires (phosphor bronze, beryllium copper) for electronic components all benefit from the dimensional precision and electrical conductivity of cold drawn products. Global electronics industry consumes over 20 million tons of cold drawn wire annually.

Energy Sector: Hydraulic tubing (operating pressures 3000-10,000 psi), instrument tubing (±0.05mm tolerance), and control line tubing for oil and gas applications frequently specify cold drawn seamless tube for superior mechanical properties and corrosion resistance. Nuclear applications also utilize cold drawn products for critical piping systems requiring ASME Section III certification, with wall thickness tolerances of ±7.5%.

Maintaining consistent quality in cold drawing operations requires comprehensive testing and inspection protocols aligned with international standards:

Dimensional Inspection: Micrometers (resolution 0.01mm), calipers, and coordinate measuring machines (CMM with accuracy ±0.002mm) verify that products meet specified tolerances. Automated optical or laser measuring systems (measuring frequency 100-1000 points/second) provide continuous monitoring during production for high-volume operations, detecting deviations within 0.001mm.

Surface Quality Assessment: Visual inspection per ASTM A450 standards identifies scratches, laps, or other surface defects exceeding 0.1mm depth. Profilometers measure surface roughness quantitatively (measuring range Ra 0.05-10 μm), ensuring specifications are met. Eddy current testing (sensitivity 0.2mm deep) or magnetic particle inspection detects subsurface defects in critical applications.

Mechanical Properties Testing: Tensile testing per ASTM E8/ISO 6892 standards determines yield strength (accuracy ±2%), ultimate tensile strength, and elongation (typical range 10-40% after cold drawing). Hardness testing using Rockwell (HRB/HRC scales), Brinell (typical range 150-400 HB), or Vickers (100-600 HV) methods provides rapid assessment of work hardening effects with testing frequency of 1 sample per 2-5 tons production. For critical applications, additional tests may include Charpy impact resistance (testing temperature -40°C to +20°C), fatigue strength (testing cycles 10⁶-10⁷), or stress corrosion cracking susceptibility per NACE standards.

Metallurgical Examination: Microscopic evaluation at 100-500X magnification of polished and etched cross-sections reveals grain structure, deformation patterns, and internal defects. Grain aspect ratios of 3:1 to 10:1 (elongated to transverse) are typical after cold drawing. This analysis helps optimize process parameters and troubleshoot quality issues, with typical examination frequency of 1 sample per production batch.

Non-Destructive Testing (NDT): Ultrasonic testing (UT with frequency 2-10 MHz, sensitivity 1mm defect), radiography, or electromagnetic methods detect internal flaws without damaging products. These techniques are particularly important for safety-critical applications in aerospace (per AMS specifications), nuclear (ASME Section III), or medical (ISO 13485) fields, with 100% inspection often required.

Understanding potential defects enables manufacturers to implement preventive measures and reduce scrap rates from typical 3-5% to below 1%:

| Defect Type | Characteristics | Common Causes | Prevention Methods |

|---|---|---|---|

| Center Burst (Chevron Cracks) | Internal cracking along centerline at 45° angle | Excessive reduction (>35%), die angle too large (>20°) | Limit reduction to 20-25% per pass, use die angles 12-16°, ensure proper lubrication |

| Surface Scratches | Longitudinal marks 0.01-0.5mm deep | Die wear, contaminated lubricant (particles >0.05mm), poor feedstock surface | Replace dies after 100-500 tons, use filtration systems (10-25 micron), inspect feedstock (Ra < 6 μm) |

| Die Lines | Spiral or circumferential marks repeating at fixed intervals | Die surface damage (scratches >0.02mm), material buildup in bearing zone | Polish dies to Ra 0.2-0.4 μm, clean dies every 20-50 tons, optimize lubricant viscosity |

| Diameter Variation | Dimensions varying ±0.05-0.2mm along length | Die wear (diameter increase 0.01-0.05mm per 100 tons), speed fluctuations (±10%), temperature changes (±20°C) | Monitor die wear with laser gauges, stabilize speed to ±2%, control temperature ±5°C, replace dies at 80% wear limit |

| Seams and Laps | Folded-over surface defects 0.1-2mm deep | Defects in starting material (seams >0.2mm), excessive reduction causing surface folding | Inspect feedstock with eddy current testing, limit reduction to 25% for seam-prone materials, improve surface preparation |

| Work Hardening Cracks | Surface or edge cracking, hardness >35 HRC | Excessive cumulative reduction (>70% without annealing), insufficient annealing (time/temperature) | Anneal at 650-750°C for 2-6 hours after 50-60% reduction, verify hardness<25 HRC before resuming |

Cold drawing operations utilize specialized equipment designed for specific product types and production volumes, with capital investments ranging from $50,000 for basic wire drawing machines to $2+ million for advanced tube drawing lines:

Draw Benches: These machines feature a stationary die and a moving carriage (powered by hydraulic cylinders generating 50-500 tons force) that grips and pulls the workpiece through. Draw benches handle straight lengths of bar, tube, or rod, typically ranging from 3 to 30 meters long with drawing speeds of 5-30 m/min. They're ideal for producing precision bar stock where straightness tolerance of 0.3mm/meter is critical. Production capacity ranges from 100-500 tons/month depending on size.

Bull Blocks: Rotating drum-type machines (drum diameters 1-3 meters) wind drawn wire or small-diameter rod onto the drum surface. Bull blocks enable continuous operation for coil-to-coil processing and suit high-volume wire production with speeds up to 15 m/sec and capacities of 200-1000 tons/month for fine wire.

Chain Drawing Machines: Continuous chain mechanisms (chain speeds 10-50 m/min) grip and pull material through dies in a straight-line configuration. These machines combine elements of draw benches and continuous processing, offering flexibility for various product sizes from 5mm to 100mm diameter with production rates of 150-600 tons/month.

Multiwire Drawing Machines: Specialized equipment for wire drawing that processes material through a series of progressive dies (typically 8-20 dies) in tandem. Modern multiwire machines achieve area reductions of 85-95% in a single pass through the machine at speeds up to 30 m/sec for fine wire (0.1-2mm diameter). Production capacity can reach 50-200 tons/day for medium wire sizes.

Tube Drawing Equipment: Specialized machines incorporating mandrels (fixed or floating), plugs (ball or cylindrical), or other internal tooling to control both inside diameter (ID tolerance ±0.05-0.15mm) and outside diameter (OD tolerance ±0.025-0.10mm) of tubular products. These machines are essential for producing cold drawn seamless tube with precise wall thickness control (tolerance ±5-10%) and operate at speeds of 10-60 m/min with monthly capacities of 50-300 tons depending on tube size and complexity.

The cold drawing industry continues evolving with technological advances that promise to enhance efficiency, quality, and sustainability:

Advanced Materials: Development of new alloys including high-entropy alloys, advanced high-strength steels (AHSS with tensile strength >1500 MPa), and metal matrix composites expands cold drawing applications. Specialized materials for extreme environments (operating temperatures -200°C to +800°C), enhanced electrical conductivity (>105% IACS), or unique mechanical properties (shape memory alloys) drive innovation in process technology and require novel lubrication and die material solutions.

Automation and Digital Integration: Industry 4.0 technologies including automated inspection (defect detection accuracy >99%), real-time process monitoring (measuring 50+ parameters continuously), and predictive maintenance (predicting failures 7-14 days in advance) optimize production efficiency by 15-25% and quality consistency. Machine learning algorithms analyze production data to predict die wear (accuracy ±5%), optimize process parameters (reducing defects by 20-40%), and reduce scrap rates from typical 3-5% to below 1%. Digital twin technology enables virtual process optimization before physical trials, reducing development time by 30-50%.

Environmental Sustainability: Advances in lubricant technology focus on reducing environmental impact through biodegradable formulations (>90% biodegradability in 28 days) and closed-loop recycling systems that reduce lubricant consumption by 40-60%. Energy-efficient equipment designs incorporating variable frequency drives (VFDs) and regenerative braking minimize power consumption by 20-35% while maintaining or increasing productivity. Some modern facilities achieve 80-90% water recycling and 95% lubricant recovery rates.

Advanced Die Materials and Coatings: New die materials including polycrystalline diamond (PCD) dies for wire drawing (tool life 50-100 times conventional carbide), ceramic composites for aluminum processing, and advanced coatings like diamond-like carbon (DLC with friction coefficient 0.05-0.10) or titanium nitride (TiN) enable processing of difficult materials and reduce production costs by extending die life from typical 100-200 tons to 500-2000+ tons. These innovations also improve surface finish by 20-40% (achieving Ra 0.2-0.8 μm) and reduce drawing force by 10-25%.

Precision Engineering: Continued refinement of die design methodologies using computational fluid dynamics (CFD) and finite element analysis (FEA with accuracy ±5%) enables virtual process optimization before physical production begins, reducing development time and costs by 40-60%. Advanced manufacturing techniques including electrical discharge machining (EDM with tolerance ±0.005mm) and laser surface treatment enable die geometries achieving tolerances of ±0.01mm and surface finishes of Ra 0.1-0.3 μm, pushing the boundaries of achievable product quality.

The cold drawing process remains a cornerstone of modern metal manufacturing, offering unmatched dimensional precision (tolerances to ±0.025mm), superior surface quality (Ra 0.4-1.6 μm), and enhanced mechanical properties (strength increases of 20-50%). From wire thin as 0.025mm to robust bars 150mm in diameter, this versatile technique transforms raw materials into high-performance products across countless industries, with global production exceeding 100 million tons annually.

Success in cold drawing depends on understanding the complex interplay between material properties, process parameters (reduction ratio 15-30%, die angles 12-16°, drawing speeds 10-100 m/min), tooling design, and quality control. Whether producing cold drawn seamless tube for critical applications requiring wall thickness tolerances of ±5-10%, precision bar stock for machining with concentricity within 0.05mm, or fine wire for electronics with diameters down to 0.025mm, manufacturers must carefully balance multiple variables to achieve optimal results while maintaining scrap rates below 2% and production costs competitive with alternative processes.

As technology advances and new materials emerge, the fundamentals of cold drawing continue proving their value. Investment in proper equipment ($50,000-$2+ million depending on application), skilled personnel, and comprehensive quality systems (including tensile testing, dimensional inspection, and metallurgical analysis) positions manufacturers to leverage this process for competitive advantage. With ongoing innovations in automation (increasing efficiency 15-25%), advanced die materials (extending tool life 3-10 times), and sustainable practices (reducing environmental impact by 30-50%), the cold drawing process will undoubtedly continue playing a vital role in metal manufacturing for decades to come, adapting to meet evolving industrial needs while maintaining its reputation for precision, efficiency, and reliability.

Cold drawing occurs at room temperature (below 30% of melting point) and produces superior surface finish (Ra 0.4-1.6 μm vs 6-25 μm), tighter tolerances (±0.05mm vs ±0.5mm), and increased strength through work hardening (20-50% increase). Hot drawing requires heating material above recrystallization temperature (typically 800-1200°C), allowing larger reductions per pass (40-60%) but producing lower dimensional accuracy and requiring additional finishing operations.

Tensile strength typically increases 20-50% and yield strength increases 30-60% compared to annealed material, depending on reduction ratio and composition. Low carbon steel can increase from 300 MPa to 450-500 MPa yield strength (40-67% increase), while some stainless steels (304/316) may see increases from 200 MPa to 450+ MPa (>125% increase) with proper processing and multiple passes.

Lubrication reduces friction coefficients from 0.3-0.5 (dry) to 0.05-0.15 (lubricated), cutting drawing forces by 30-40% and extending die life 3-5 times. It prevents surface defects (scratches, galling), controls temperature rise (limiting to 50-100°C), and facilitates smooth metal flow. Without proper lubrication, excessive die wear occurs (reducing tool life by 60-80%), surface quality deteriorates (Ra >3 μm), and production interruptions increase significantly.

Cold drawing consistently achieves dimensional tolerances from ±0.025mm for precision small components to ±0.13mm for larger products, with surface finishes of Ra 0.4-1.6 micrometers. Specific examples: wire drawing achieves ±0.01-0.05mm, precision bar stock achieves ±0.05-0.10mm, and cold drawn seamless tube achieves OD tolerance ±0.05mm and wall thickness ±5-10%. These tolerances often eliminate secondary machining, reducing manufacturing costs 15-30%.

Annealing becomes necessary when work hardening makes material too hard (typically >35 HRC) for further reduction without cracking. Materials with high work hardening rates like stainless steel (304/316) require annealing after 30-40% total reduction, while more ductile materials (low carbon steel, copper) may withstand 60-80% reduction before annealing. Annealing typically occurs at 650-750°C for 2-6 hours, restoring ductility and reducing hardness to<25 HRC.

Most operations use 15-30% area reduction per pass to balance productivity with material formability and prevent defects. Softer materials like annealed copper may tolerate 30-35%, brass 30-40%, while harder materials like stainless steel limit reductions to 15-25%, and nickel alloys to 12-20%. Reductions exceeding 35% risk center bursting, surface cracking, and excessive work hardening requiring immediate annealing.

Most ductile metals with elongation >10% can be cold drawn, including steel, stainless steel, copper (elongation 30-50%), aluminum, brass, and nickel alloys. Brittle materials with elongation<5% (cast iron, some tool steels) or those with extremely high work hardening rates (some precipitation-hardened alloys) prove difficult or impossible to cold draw and require alternative forming methods like hot working, machining, or powder metallurgy.