close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-03-25 Origin: Site

Hydraulic systems are the backbone of many industries. They power machinery, from construction equipment to aerospace components.

At the heart of these systems are hydraulic cylinders. And a key component of these cylinders? Honed tubes.

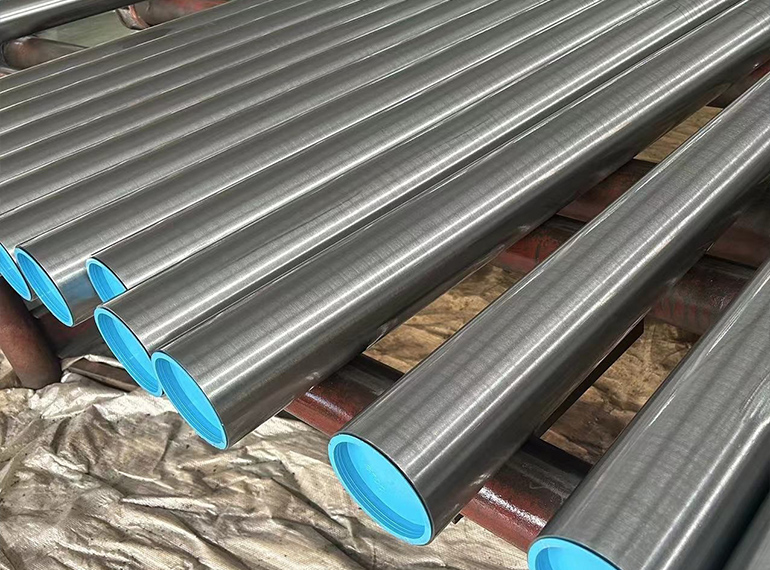

Honed tubes are precision-engineered for optimal performance. Their smooth interior surface reduces friction, enhancing the efficiency and lifespan of hydraulic systems.

In this article, we'll delve into the benefits of using honed tubes in hydraulics. We'll explore their role in hydraulic cylinders, their impact on system performance, and why they're a smart choice for businesses relying on hydraulic machinery.

Precision is crucial in hydraulic cylinders. Honed tubes are essential for achieving the necessary accuracy and consistency.

The honing process refines the tube's interior surface, ensuring it meets tight geometric specifications. This precision reduces component wear.

Smooth surfaces in honed tubes prevent damage to hydraulic cylinder parts. They offer a perfect environment for efficient operation.

Accurate dimensions of honed tubes ensure seamless movement of piston rods. This precision enhances responsiveness and control in hydraulic systems, crucial for demanding applications.

Honed tubes are known for their exceptional durability and performance. These tubes withstand high-pressure conditions common in hydraulics.

Their robust construction reduces wear and tear on hydraulic cylinder parts. This durability extends the cylinder's life.

The precision of honed tubes allows for effective pressure handling. This ensures consistent operations under variable loads.

Honed tubes enhance performance by reducing energy losses. Their smooth surfaces minimize friction, contributing to system efficiency.

Reduced wear and tear

Improved pressure handling

Minimized energy losses

Utilizing honed tubes in hydraulics leads to significant cost savings. Their precision reduces the frequency of maintenance requirements.

Honed tubes contribute to longer equipment lifespan. This reliability results in less downtime and enhanced productivity.

Investing in quality honed tubes proves economical in the long run. The reduced need for repairs and replacements underscores this benefit.

Lower maintenance costs

Increased equipment lifespan

Honed tubes offer an exceptional surface finish essential for creating airtight seals. This precision prevents hydraulic fluid from leaking.

The enhanced sealing capabilities ensure operational efficiency. Reliable seals contribute to maintaining consistent system pressure.

With honed tubes, hydraulic systems experience fewer performance disruptions. This feature minimizes the risk of costly fluid leaks and contamination.

Honed tubes offer a wide range of customization options. Their adaptability makes them suitable for diverse hydraulic applications.

Manufacturers provide honed tubes in various grades and dimensions. This flexibility allows for precise matching to specific system requirements.

For unique hydraulic setups, custom-made honed tubes are available. They ensure optimal compatibility, enhancing the overall system performance.

Various grades and dimensions

Custom-made options

Honed tubes find extensive use across multiple industries. Their functionality is critical in aerospace, automotive, and manufacturing sectors.

The aerospace industry benefits from the precision of honed tubes. They ensure reliability in high-pressure hydraulic systems.

Recent technological advancements have improved the honing process. This has enhanced the performance characteristics of honed tubes.

Aerospace, automotive, and manufacturing industries

Advancements in honing technology

Incorporating honed tubes in hydraulics offers strategic benefits. Their precision and reliability enhance the performance of hydraulic systems significantly.

Choosing honed tubes for hydraulic applications is a smart investment. They contribute to increased productivity and reduce operational costs.

For this type of tubes please call us (+86 13616125265) or send us an email to jianjun.c@czchengxin.com and we will give you a budget according to your needs.