close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

You need strong and dependable materials for tough jobs. E355 steel tubes are very strong and have exact sizes. These tubes are part of the low-alloy, high-strength steel group. Tube e355 is special because it can hold heavy weight. It also works in many different areas. You see it used in building, machines, and transport. The table below shows why e355 is special:

Characteristic | Description |

|---|---|

Yield Strength | At least 355 MPa (if thickness is 16mm or less) |

Tensile Strength | Between 470 and 630 MPa |

Elongation | At least 21% |

Toughness | Works in cold places, even down to -40°C |

Processability | Simple to cut, weld, and shape |

E355 steel tubes are very strong and dependable. They work well for tough jobs in building, machines, and hydraulic systems. These tubes have high yield and tensile strength. This means they can hold heavy weight without bending or breaking. E355 steel tubes are simple to use. You can cut, weld, and shape them with regular tools. This makes them useful for many different projects. Always look for EN 10305-1 certification when picking E355 tubes. This helps you get safe and good-quality materials. The special chemical makeup of E355 steel makes it tough. It also helps the tubes resist rust, so they work well in rough places.

You often need a material that can handle heavy loads and tough conditions. E355 steel gives you this strength. This steel belongs to the high-strength, low-alloy group. You find tube e355 used in many industries because it offers both power and reliability. The microstructure of e355 helps it stand out. The fine grain structure gives you better toughness and impact resistance. When you use tube e355, you get a material that works well in both normal and extreme environments.

Tip: The normalized condition of e355 steel ensures that you get consistent quality with fewer internal flaws.

Here is a table that shows how the microstructure affects the performance of e355 steel:

Property | Description |

|---|---|

Strength-to-weight ratio | E355 steel is known for its impressive strength-to-weight ratio, making it ideal for structural elements. |

Toughness | The fine grain structure provides improved toughness and impact resistance. |

Normalized condition | Ensures consistency in material properties, minimizing internal flaws. |

You want to know what makes tube e355 so useful. The answer lies in its chemical makeup and mechanical properties. The chemical composition follows strict rules to make sure you get a high-strength product every time. Here is a table that shows the main elements in tube e355:

Element | Percentage |

|---|---|

Carbon (C) | 0.22 max |

Silicon (Si) | 0.55 max |

Manganese (Mn) | 1.60 max |

Phosphorus (P) | 0.025 max |

Sulfur (S) | 0.025 max |

These elements work together to give tube e355 its high-strength and toughness. You also get good weldability and machinability, which means you can cut, shape, and join the tubes easily.

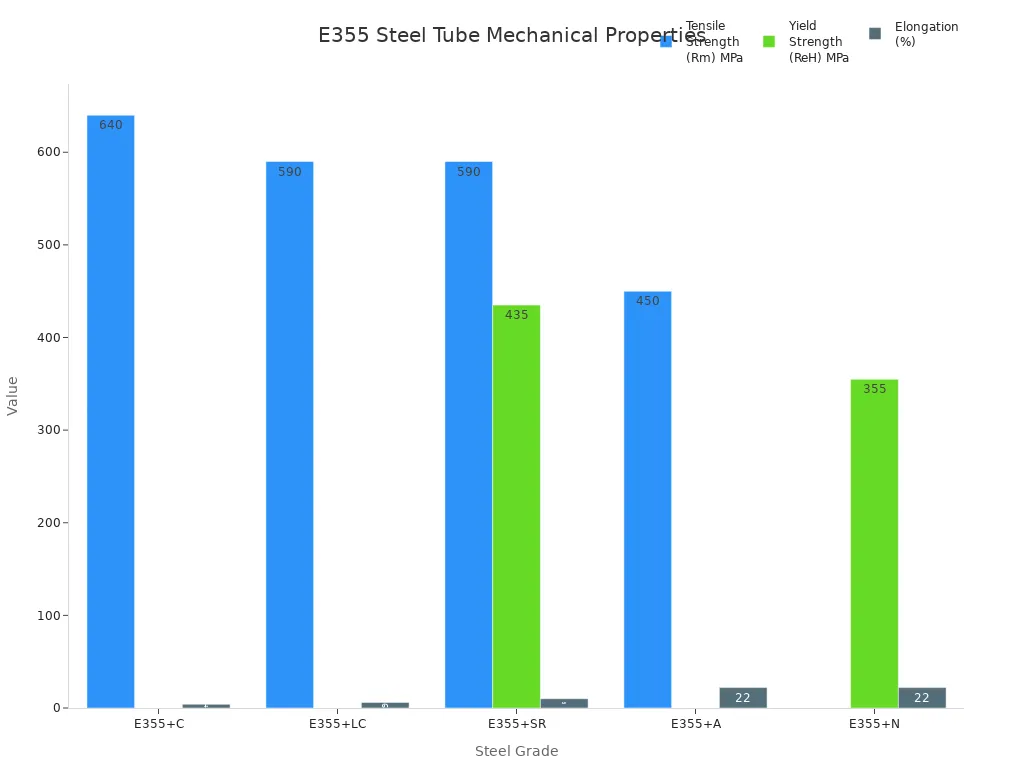

Mechanical properties are just as important. You need to know how much force the tube can handle before it bends or breaks. The table below shows the tensile strength, yield strength, and elongation for different grades of tube e355:

Steel Grade | Tensile Strength (Rm) MPa | Yield Strength (ReH) MPa | Elongation (%) |

|---|---|---|---|

E355+C (Cold drawn/hard) | 640 | N/A | 4 |

E355+LC (Cold drawn / soft) | 590 | N/A | 6 |

E355+SR (Cold drawn and stress relieved) | 590 | 435 | 10 |

E355+A (Soft annealed) | 450 | N/A | 22 |

E355+N (Normalized) | 490-630 | 355 | 22 |

You can also see these values in the chart below:

You want to make sure you use the right material for your project. The en 10305-1 standard helps you do this. This standard sets the rules for classifying and producing tube e355. It covers both non-alloy and alloy steels, including e235 and e355. The en 10305-1 standard also enforces strict controls on chemical composition. This means you get a product that meets high-strength and quality requirements every time.

Here is a list of key points about en 10305-1:

en 10305-1 governs the classification of E355 steel tubes.

It includes both non-alloy and alloy steels, such as E235 and E355.

The standard enforces stricter chemical composition controls.

en 10305-1 ensures that tube e355 meets high-strength and precision needs.

You can trust tube e355 made under en 10305-1 for demanding applications.

en 10305-1 covers seamless cold drawn steel tubes, which are used in hydraulic and mechanical systems.

The standard helps you choose the right tube for safety and performance.

en 10305-1 gives you confidence in the quality and reliability of tube e355.

When you see en 10305-1 on a product, you know it meets strict European standards.

Note: Always check for en 10305-1 certification when you select tube e355 for your project. This ensures you get the best quality and performance.

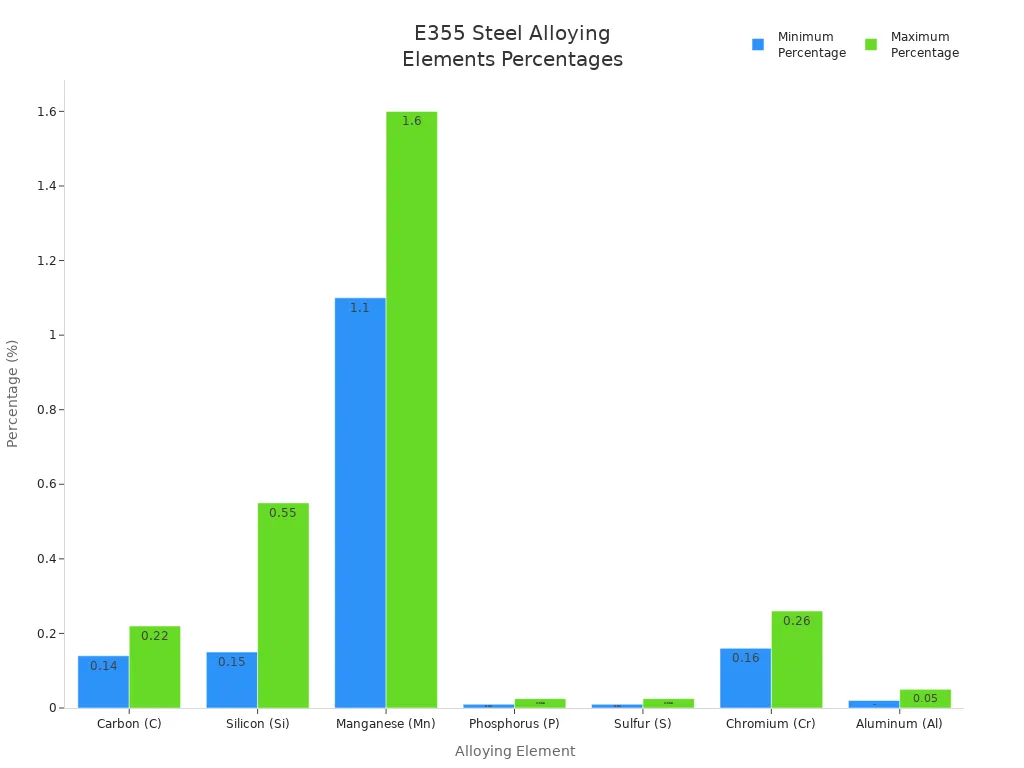

It is important to know why e355 steel tubes are strong. The mix of alloying elements makes them reliable. Each element helps change how the tube works. The table below shows the main elements and their percentage ranges:

Alloying Element | Minimum Percentage | Maximum Percentage |

|---|---|---|

Carbon (C) | 0.14% | 0.22% |

Silicon (Si) | 0.15% | 0.55% |

Manganese (Mn) | 1.10% | 1.60% |

Phosphorus (P) | 0.010% | 0.025% |

Sulfur (S) | 0.010% | 0.025% |

Chromium (Cr) | 0.16% | 0.26% |

Aluminum (Al) | 0.020% | 0.050% |

You can look at the chart below to compare these elements:

Note: When the elements are balanced, the tube is tough, strong, and easy to use.

You may ask how these elements change the steel tube. The answer is simple. Each element affects strength, toughness, and how easy it is to work with. The table below shows how carbon, silicon, and manganese help:

Element | Content Range | Effect on Properties |

|---|---|---|

Carbon (C) | ≤ 0.22% | Changes strength and toughness of the steel pipe. |

Silicon (Si) | ≤ 0.55% | Makes the steel pipe stronger and harder. |

Manganese (Mn) | ≤ 1.6% | Improves strength, toughness, and workability. |

Other elements also help the tube. Here is what they do:

Chromium makes the tube stronger, harder, and protects it from rust and wear.

Nickel helps the tube stay strong, hard, and keeps it from rusting.

Molybdenum adds strength, toughness, and stops damage from corrosion and creep.

Manganese makes the tube stronger, harder, and helps it last longer.

Vanadium makes the tube stronger, helps it last longer, and lets it handle shocks.

When you pick e355 steel tubes, you get a tube that can hold heavy weight and work in tough places. The special mix of elements makes the tube work well every time.

You need strong tubes for hard jobs. E355 steel has high mechanical strength. This means it can hold heavy loads. It does not bend or break easily. When you compare it to other grades, E355 is much stronger. Look at the table below:

Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

E355 (+N) | 355 | 490–630 |

E235 (+N) | 235 | 340–480 |

You can trust E355 to work well under pressure. This strength makes it great for hydraulic systems. It is also used in building and machines that work hard every day.

Tip: High yield and tensile strength give you safety and trust in your projects.

Precision steel tubes help you get exact results. These tubes have tight tolerances. This means every piece fits just right. The way they are made uses careful steps. Each tube must meet strict rules. Here is how the process works:

Process Type | Description |

|---|---|

Raw Materials Selection | Uses cold-drawn seamless tubes with special grades for strength and shape. |

Material Pre-treatment | Surface treatments reduce friction and keep wall thickness even. |

Cold Drawing Forming Process | Special dies and controls prevent stress and keep the tube strong. |

Heat Treatment Strengthening | Quenching and tempering make the tube tough and balanced. |

Inner Hole Finishing | Diamond honing gives a smooth, round inside for better flow. |

Surface Strengthening | Electroplating protects against rust and harsh conditions. |

Quality Inspection | Careful testing checks strength and size accuracy. |

You also get very tight tolerances. For example, a tube with a 4 mm diameter can have a tolerance of just ±0.05 mm. This level of precision means you can use these tubes in systems where every millimeter counts.

Seamless cold drawn steel tubes have many good points. They are stronger than welded tubes. They also resist rust better. The cold drawing process makes the surface smoother. It also makes the size more exact. Here is a quick comparison:

Seamless Tubes | Welded Tubes |

|---|---|

Higher in strength | Lower in strength |

High corrosion resistance | Prone to corrosion |

Better pressure capacity | 20% less pressure capacity |

Extremely durable | Lower durability |

More pure steel | Less purity |

You get a tube that can handle high pressure. It also works well in tough places. The cold drawing process makes the tube last longer. It also helps the tube work better in important jobs.

When you pick seamless cold drawn steel tubes, you get top performance, safety, and long life.

Tube e355 is used a lot in hydraulic systems. These systems need tubes that can take high pressure. The inside of tube e355 is very smooth. This helps the fluid move without slowing down. Strong tubes like these can handle heavy use. Your hydraulic cylinders stay safe and work well, even when the job is hard.

Smooth inside helps fluid move fast.

Strong tubes can take heavy loads again and again.

Tubes work well in high-pressure hydraulic cylinders.

Tip: Using tube e355 in hydraulic systems helps your machines last longer and work better.

Tube e355 is used in many building and bridge projects. Builders pick these tubes for tall buildings and bridges. They need strong and tough materials. Tube e355 can hold heavy weight and does not bend easily. These tubes help spread out force so buildings stay safe.

Application | Description |

|---|---|

High-rise buildings | |

Bridge | These tubes help bridges stay strong for a long time. |

Structural systems | Tube e355 bracing spreads force and stops bending. |

These tubes also fight rust, so buildings last longer. Tube e355 works in many types of building frames. You can use it for beams and columns.

Strong and tough

Good for many building frames

Fights rust

Mining needs tubes that can work in rough places. Tube e355 can take high pressure and heat. These tubes do not rust easily, so they work well underground or in wet spots. Tube e355 is made with care, so you can trust it for hard mining jobs.

Handles high pressure and heat

Does not rust in tough places

Made with care for hard jobs

Note: Tube e355 helps mining tools last longer and work better, even when the job is rough.

Tube e355 is used in machines and airplanes because it is strong and made to exact sizes. Car makers use these tubes for prop shafts and drive shafts. Factories use tube e355 for hydraulic cylinders because they need smooth and exact tubes. Airplane engineers pick tube e355 for important parts that need to be strong and exact.

Needed for car making pipes

Used in airplane and military parts

Property | Value |

|---|---|

640 min. | |

Yield Point (N/mm²) | 540 min. |

Elongation (min. %) | 4 |

E355 steel tubes help keep airplane parts safe. The high strength means tubes will not break under stress. The way these tubes are made gives you exact sizes and smooth surfaces. This helps your machines work well every time.

When you use tube e355 in machines and airplanes, you get safety, good work, and tubes that last a long time.

When you pick E355 steel tubes, you get strong and exact tubes. These tubes are very reliable and work in many jobs. They are great for holding heavy things and for other uses. The table below shows why these tubes are special:

Property | Details |

|---|---|

As close as ±0.05 mm | |

High strength | Handles heavy loads and stress |

Smooth surface | Reduces friction and wear |

Consistent quality | Follows strict EN10305 standards |

E355 steel tubes are good for projects that need to be strong and exact. You should always check if the tubes are high quality and have the right certificates. Good customer service is also important when you choose a supplier. Chengxin is a good choice for E355 honed tubes and can help your project turn out well.

E355 steel tubes have higher strength and tighter tolerances. You get better performance in heavy-duty jobs. These tubes also resist bending and breaking more than regular steel tubes.

Yes, you can weld and machine E355 steel tubes with standard tools. The tubes have good weldability and machinability. You get clean cuts and strong joints.

You find E355 steel tubes in hydraulic systems, construction, mining, and machinery. These tubes work well in places that need strength and precision.

Look for the EN 10305-1 mark on the tube or ask your supplier for a certificate. This mark shows the tube meets strict quality and safety rules.