close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2024-11-19 Origin: Site

The manufacturing world is full of intricate processes. One such process is the creation of cold drawn seamless tubing. This high-strength, precision product is a cornerstone in various industries.

But what exactly is cold drawn seamless tubing? And how is it made? This article aims to answer these questions, providing a detailed look at the manufacturing process.

From the initial creation of a solid billet to the final product, we'll explore each step. Let's delve into the fascinating world of seamless manufacturing.

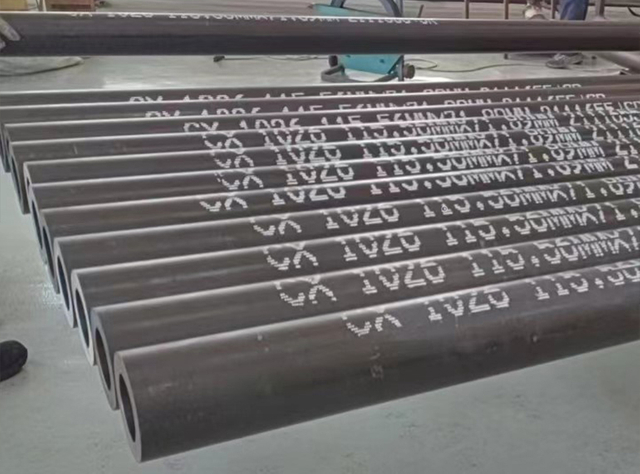

Cold drawn seamless (CDS) tubing is known for its strength and precision. It is made without any welds or joints, resulting in superior structural integrity.

The cold drawing process refines the tube's dimensions. This ensures uniformity and accuracy, which is crucial for applications requiring tight tolerances.

CDS tubing is used in various industries. It is particularly valued in sectors where high pressure and precision are essential. This includes automotive, aerospace, and hydraulic systems.

The manufacturing of cold drawn seamless tubing begins with selecting the right raw material. The process involves several precise steps, starting with creating a solid billet.

Each stage enhances the tube's properties. This includes mechanical strength and surface finish, essential for quality.

The seamless manufacturing process is complex. However, it ensures the production of a high-performance product that can withstand demanding environments.

The process starts with producing a steel billet. This billet forms the foundation of the tube.

High-quality steel is used to cast the billet. This ensures the integrity and durability of the final product.

Next, the solid billet undergoes a piercing process. This transforms it into a hollow tube.

The piercing creates the primary structure. This step is crucial for forming the mother tube efficiently.

Once the hollow tube is ready, the cold drawing begins. This step further shapes the tube.

Drawing refines the tube’s dimensions and improves its mechanical properties. It requires precise control and skilled operation.

Multiple drawing passes are often needed. Each pass enhances accuracy and consistency in the tube's dimensions.

Refining Dimensions and Mechanical Properties

The tube's dimensions are precisely refined during drawing. This ensures that the tube meets rigorous standards.

Mechanical properties improve through work hardening. This results from the forces applied in the drawing process.

Annealing follows the cold drawing, relieving stress in the tube. This process enhances ductility and workability.

Surface treatment is also performed. It improves the tube's finish and protects against corrosion.

In this final step, the tube undergoes strict checks. Ensuring it meets all specified dimensions and tolerances is crucial.

Precision is essential here. Any inconsistencies can affect the performance in its intended applications.

Cold drawn seamless tubing offers significant advantages in industrial applications. Its strength and precision make it ideal for critical environments.

This manufacturing process ensures reliability and efficiency. As a result, it is preferred in sectors demanding high performance.

Cold drawing increases the tensile strength and yield of the tubing. This enhances its ability to endure high pressures.

Precision in dimensions allows seamless integration into complex systems. This accuracy minimizes the risk of failure during operation.

The process delivers a smooth surface finish. This quality is crucial for reducing friction in dynamic applications.

Moreover, the consistency in production ensures each tube meets rigorous standards. This guarantees performance uniformity across extensive projects.

Cold drawn seamless tubing finds usage in a variety of industries due to its precise and reliable nature. It is crucial for high-pressure applications in hydraulic and pneumatic systems, where integrity is essential.

Moreover, automotive and aerospace industries benefit from its consistent performance. These fields require components that can withstand demanding conditions without failure, making CDS tubing a preferred choice. Its adaptability in diverse settings highlights its versatility and indispensable role in modern manufacturing.

Cold drawn seamless tubing stands at the forefront of precision manufacturing. Its unmatched attributes in strength, accuracy, and durability make it invaluable for critical industries.

The seamless manufacturing process ensures consistent quality and performance. This process allows for innovations and advancements, pushing the boundaries of what's possible in engineering and construction.